Historical Overview of Inventory Management Practices

Modern Inventory Management Strategies

Advances in technology have transformed how businesses approach inventory management. Tools like automation and artificial intelligence enhance accuracy and efficiency, allowing organisations to predict demand more effectively. Real-time data tracking enables more informed decisions, reducing excess stock and minimising waste. Cloud-based solutions foster collaboration among teams, making information more accessible across departments and geographical locations.

Strategies such as Just-in-Time (JIT) and Lean inventory management have gained popularity in recent years. JIT focuses on synchronising inventory with production schedules, significantly reducing holding costs. Lean methodologies aim to eliminate waste within the supply chain, ensuring that resources are optimally allocated. These strategies empower companies to respond swiftly to market fluctuations while maintaining a streamlined inventory system.

Techniques Employed in Contemporary Businesses

Contemporary businesses utilise a variety of sophisticated techniques to enhance their inventory management. One prevalent method is the implementation of just-in-time (JIT) inventory systems. This approach minimises storage costs by ensuring that materials and products arrive precisely when needed. Alongside JIT, companies often rely on advanced forecasting models. These models leverage historical data and market trends to predict demand accurately, reducing the risk of overstocking or stockouts.

Another technique gaining traction is the use of automated inventory management systems. Such systems incorporate technology for real-time tracking and management of stock levels. RFID (Radio Frequency Identification) tags and barcoding systems are commonly employed to improve accuracy and efficiency in inventory control. Additionally, many businesses are adopting cloud-based solutions, which provide centralised access to inventory data across multiple locations. This integration enhances collaboration and visibility, empowering businesses to respond swiftly to market changes.

The Influence of Globalisation on Inventory Practices

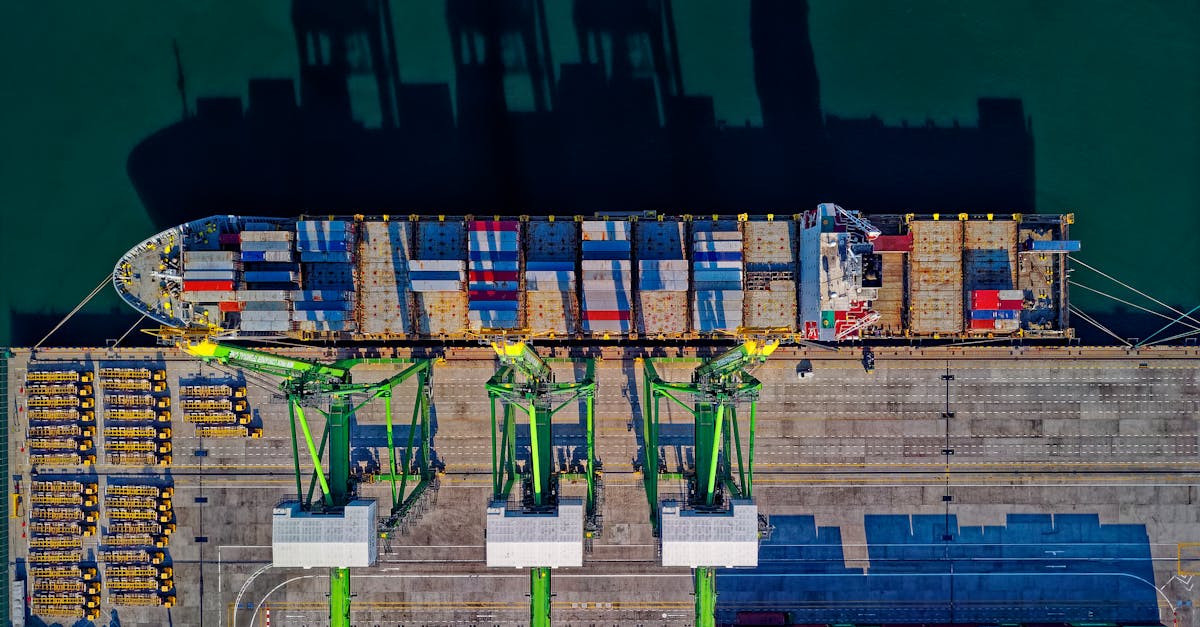

The expansion of global markets has significantly altered how businesses manage their inventories. Companies now source materials and products from suppliers located worldwide, creating a complex web of logistics that requires real-time data sharing and coordination. The need for efficiency has driven firms to adopt advanced technologies like automated inventory systems and sophisticated software solutions. These tools help track stock levels across multiple locations, ensuring timely replenishment and reducing the risk of overstock or stockouts.

As organisations navigate the intricacies of global supply chains, they face new challenges that influence inventory practices. Fluctuating exchange rates, varying regulations, and differences in lead times necessitate an adaptable inventory strategy. Businesses must also consider geopolitical issues and trade agreements, which can impact the availability of materials. This dynamic environment pushes companies to rethink traditional inventory models, emphasising agility and responsiveness to market changes while maintaining cost-effectiveness.

Managing Supply Chains Across Borders

The complexity of global supply chains has prompted businesses to adopt robust management strategies. Companies must consider various factors, including transportation costs, cultural differences, and regulatory requirements. Navigating these challenges requires an integrated approach encompassing logistics, finance, and communication. Effective collaboration with international partners becomes essential to ensure that goods move smoothly from production facilities to consumers across borders.

Technology plays a pivotal role in managing supply chains on a global scale. Advanced tracking systems allow organisations to monitor inventory levels and shipment statuses in real time. Data analytics enhances decision-making, enabling businesses to respond swiftly to market changes and demand fluctuations. By leveraging these tools, companies can optimise their operations and maintain competitiveness, ensuring customer satisfaction while minimising costs.

Sustainability and Inventory Management

The increasing awareness of environmental issues has prompted businesses to reconsider their inventory management practices. Companies are now seeking ways to reduce waste and minimise their carbon footprint through sustainable inventory strategies. This involves the adoption of eco-friendly materials and efficient stock control measures. Implementing just-in-time inventory systems can significantly diminish excess stock, which in turn lowers the likelihood of products going unsold or becoming obsolete. Additionally, utilising technology for accurate demand forecasting can help businesses maintain optimal inventory levels, further contributing to sustainability efforts.

Emphasising recycling and reusing materials comes into play as organisations begin to explore alternative approaches to traditional inventory management. Many businesses are now prioritising suppliers that adhere to sustainable practices, assuring that every element of the supply chain aligns with broader environmental goals. Educating staff on sustainable practices and encouraging a culture of environmental responsibility can foster improvements in managing inventories. Overall, the integration of sustainability into inventory management not only supports ecological initiatives but can also enhance brand reputation and customer loyalty.

EcoFriendly Approaches to Stock Control

Businesses today are increasingly adopting eco-friendly approaches to stock control, recognising the importance of sustainability in their operations. These strategies often involve the reduction of waste through more efficient inventory management practices. Techniques such as just-in-time inventory ensure that products are only ordered as needed, minimising the excess stock that typically ends up discarded.

The use of sustainable materials in packaging is another crucial aspect of eco-friendly stock control. Companies are now opting for biodegradable, recyclable, or reusable packaging options to lower their environmental footprint. Implementing technology, like inventory management software, can help track stock levels more precisely, further reducing unnecessary production and waste. Overall, these practices reflect a shift towards more responsible management of resources in the quest for environmentally sustainable operations.

FAQS

What is the historical significance of inventory management?

Inventory management has evolved significantly over the years, playing a crucial role in the efficiency of supply chains and businesses. Its historical significance lies in the ability to optimise resources, reduce waste, and improve customer satisfaction, adapting through various economic phases and technological advancements.

How have modern inventory management strategies evolved from historical practices?

Modern inventory management strategies have evolved from traditional methods, incorporating advanced technologies and data analytics. While historical practices relied on manual tracking and basic stock control, today’s approaches utilise automated systems, real-time data, and predictive analytics to enhance accuracy and efficiency.

What techniques are commonly employed in contemporary inventory management?

Contemporary inventory management employs several techniques, including just-in-time (JIT) inventory, drop shipping, and inventory optimisation software. These techniques focus on minimising holding costs, improving supply chain responsiveness, and enhancing overall inventory accuracy.

How has globalisation influenced inventory management practices?

Globalisation has significantly influenced inventory management practices by expanding supply chains across borders, requiring businesses to adapt to varied regulations, cultural differences, and logistical challenges. This has led to the adoption of more sophisticated inventory management systems to coordinate international operations effectively.

What role does sustainability play in modern inventory management?

Sustainability plays a vital role in modern inventory management as businesses increasingly focus on eco-friendly practices. Companies are adopting sustainable approaches such as reducing excess inventory, utilising recyclable packaging, and implementing energy-efficient warehousing to minimise their environmental impact.

Related Links

10 Best Practices for Effective Inventory ManagementWhy Inventory Management is Crucial for Business Success

Roundup of Top Inventory Management Strategies

Review of Leading Inventory Management Software

Why Accurate Inventory Forecasting Matters